HOW SINGER ANTI-CAV TRIM MINIMIZES DAMAGE

HOW SINGER ANTI-CAV TRIM MINIMIZES DAMAGE

Their Challenge

Pumping water at 5,310 g/m (335 l/s) with pressure beginning at 60 psi (4.1 bar) and dropping to atmosphere, it’s no wonder the City of Airdrie’s reservoir fill valve had to be replaced regularly due to serious cavitation.

“We inspected the reservoir fill valve every year for damage due to cavitation,” says Kelly McKague, City of Airdrie’s facility operator. “The valve was completely eaten away so we had to replace it every 18 months.”

Our Solution

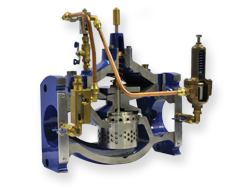

McKague decided to purchase a 12” (300 mm) Singer 2SC-PCO fitted with Singer’s Anti-Cavitation Trim. Singer Valve customized the cavitation cages to suit Airdrie’s application. Curious about its performance, McKague inspected the valve six months later. “We could have boxed the valve and resold it,” says McKague. “There was absolutely no sign of cavitation, not even on the coating. We couldn’t believe it.”

The Result

One year after installation, McKague inspected the valve again and saw no signs of damage whatsoever. Another benefit of the Singer Anti-Cavitation Trim is the noise reduction. Because cavitation is noisy—like gravel going through the valve—with the Anti-Cavitation Trim, the valve is amazingly quiet.

“THE SINGER 2SC-PCO WITH SINGER’S ANTI-CAVITATION TRIM IS DEFINITELY THE RIGHT VALVE FOR THE JOB.”

- Kelly McKague, Facility Operator, City of Airdrie

SINGER ELIMINATES CAVITATION DAMAGE IN PITTSFIELD TOWNSHIP’S RESERVOIR FILLING STATION

SINGER ELIMINATES CAVITATION DAMAGE IN PITTSFIELD TOWNSHIP’S RESERVOIR FILLING STATION SINGER VALVE STATION IS IDEAL SOLUTION

SINGER VALVE STATION IS IDEAL SOLUTION SINGER VALVE SOLVES TRIPLE DILEMA IN OHIO

SINGER VALVE SOLVES TRIPLE DILEMA IN OHIO LA COUNTY TRUSTS SINGER’S ANTI-CAV TRIM

LA COUNTY TRUSTS SINGER’S ANTI-CAV TRIM